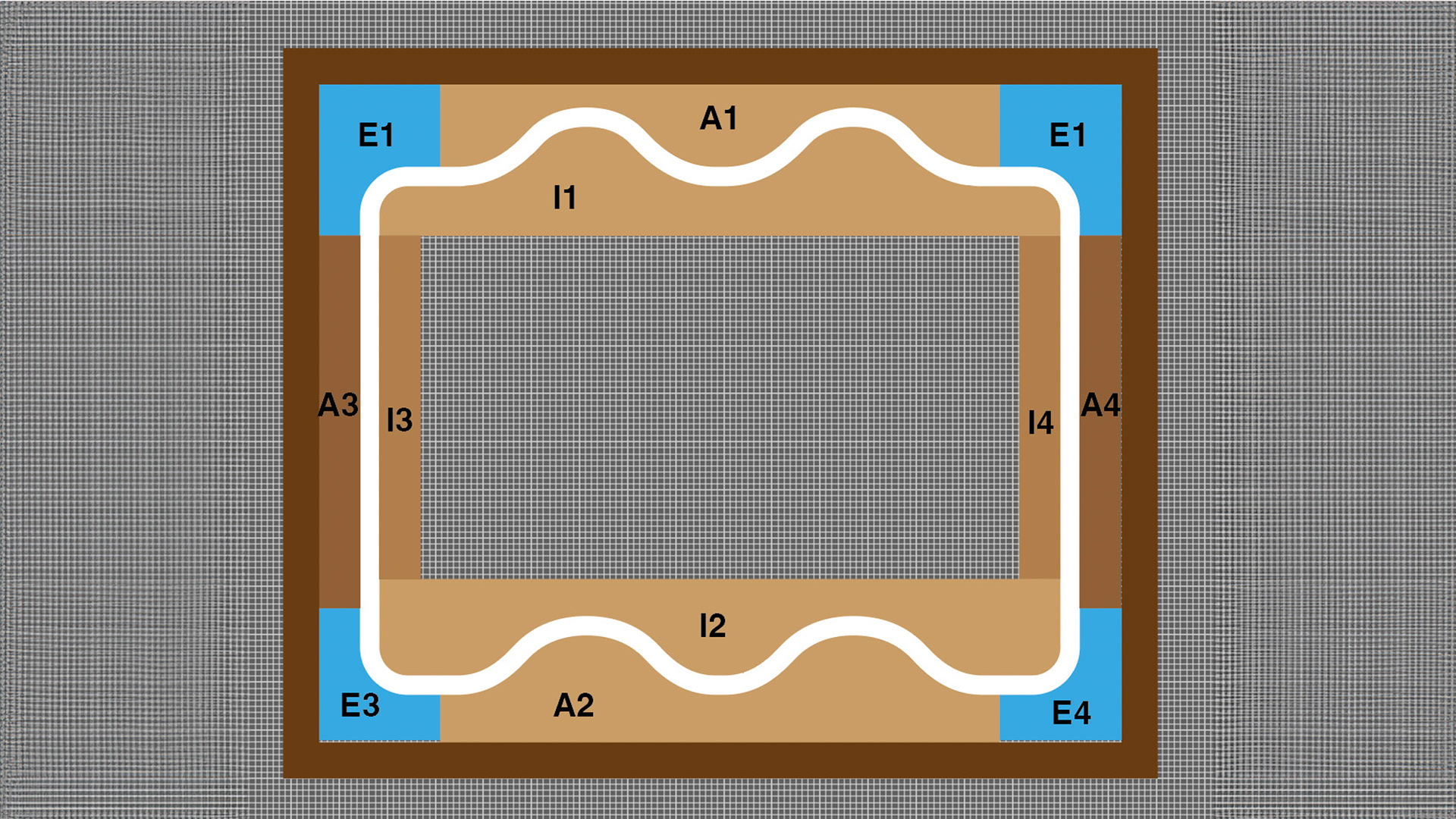

During a project I came across a wine rack designed by a well-known corrugated roof manufacturer. The minimalist yet modular concrete structure immediately caught my attention, and I set myself the challenge of recreating it with the tools and materials available to me. Using photos and a few published measurements I was able to reconstruct the form and translate it into a 3D model. Before building a casting mold, I printed a prototype to ensure that the modules would properly interlock. Once this test proved successful, I created templates from polystyrene and cut them into shape to form the outer shell of the concrete mold. A wooden framework was used to hold the elements in place so that the concrete could be poured. Despite reinforcing the mix with glass fibers, the concrete cracked several times, which meant the process only resulted in a single prototype.

Category: Prototyping, 3D-Print